Design of AC Motor Rotating Speed Monitoring System based on Internet of Things Using Blynk Application on Animal Feed Pellet Printing Machine

The student group of the Computer Engineering Technology study program at IPB University Vocational School has been conducting research for the creation of this IoT project since February 2023. The work on the tool was carried out for approximately 6 months and in collaboration with partners, namely TPST Mutiara Bogor Raya. As the name TPST or Temporary Waste Disposal Site, in this place it focuses on processing waste in Mutiara Bogor Raya Housing, but they also cultivate many animals such as catfish, laying hens, quail eggs, and also maggot..

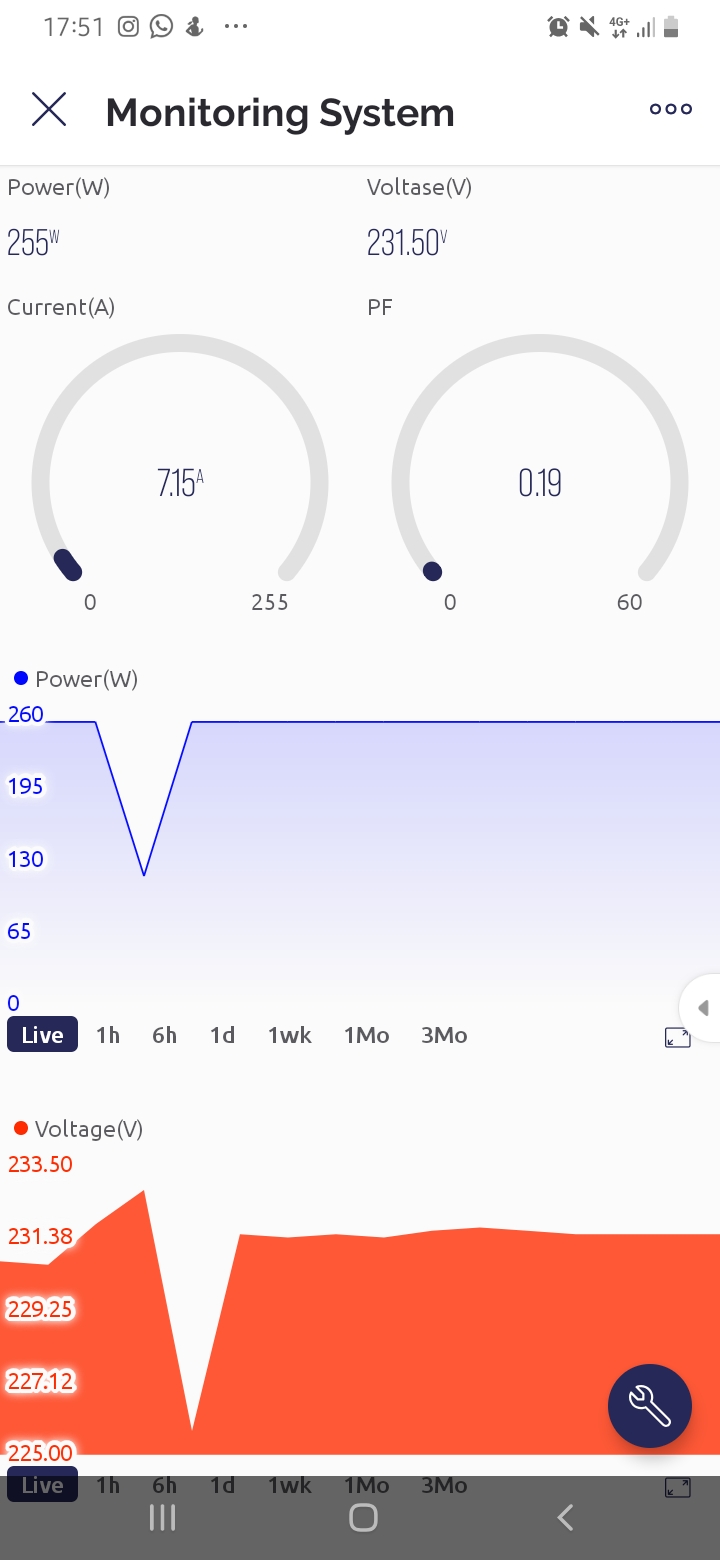

According to Sulistyowati, one of the managers of the Mutiara Bogor Raya TPST, he had a complaint about the production of maggot-based pellets. He added that for the pellet feed, he had to use the services of other parties who were quite far away to produce pellet feed from the maggot. So the student group of the Computer Engineering Technology study program tried to find a solution to make an Internet of Things-based maggot grinder. Maggot that has gone through the filter process, mixed with other ingredients to be further ground in a grinding machine. Then the maggot mixture that has been ground is cut into small pieces using the same machine. In this process, the IoT system on the machine is used. The device that is directly connected using the BLynk application can directly monitor the voltage, power, and voltage used. Workers can also adjust the voltage from the dimmer and adjust to the desired pellet size. After exiting the grinding machine, the pellets are dried and collected for distribution or consumption by catfish.

Conclusion

The Internet of Things-based AC motor rotating current speed monitoring system using the Blynk application on the animal feed pellet molding machine functions properly, by monitoring the AC motor rotating speed using a smartphone in real time. The Blynk application provides an intuitive and easy-to-use user interface. The features contained in it can help users to monitor and optimize the operation of the animal feed pellet molding machine..

This system provides significant benefits in monitoring and controlling the speed of AC motors. In the animal feed industry, proper AC motor speed can affect the quality and quantity of feed pellets produced. With this system, users can easily adjust the motor speed to ensure optimal feed pellet production.